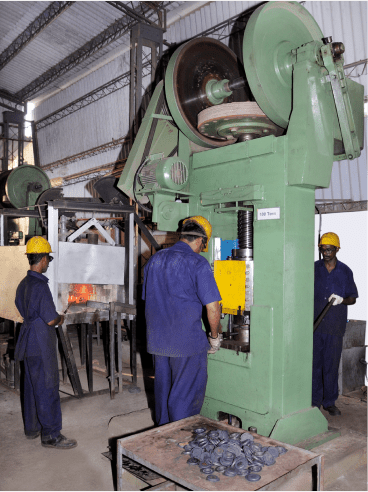

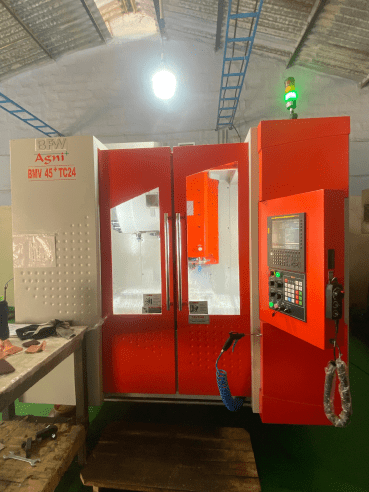

United Enterprises integrates cutting-edge equipment and avant-garde design methodologies to ensure that each component not only meets but surpasses industry standards.

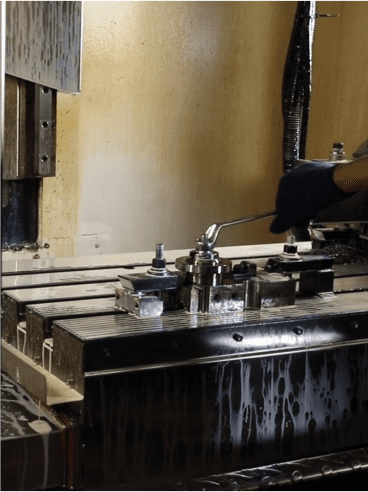

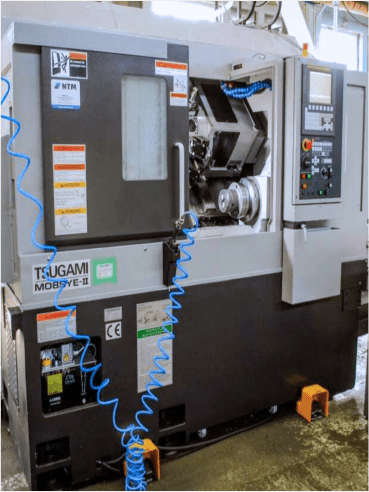

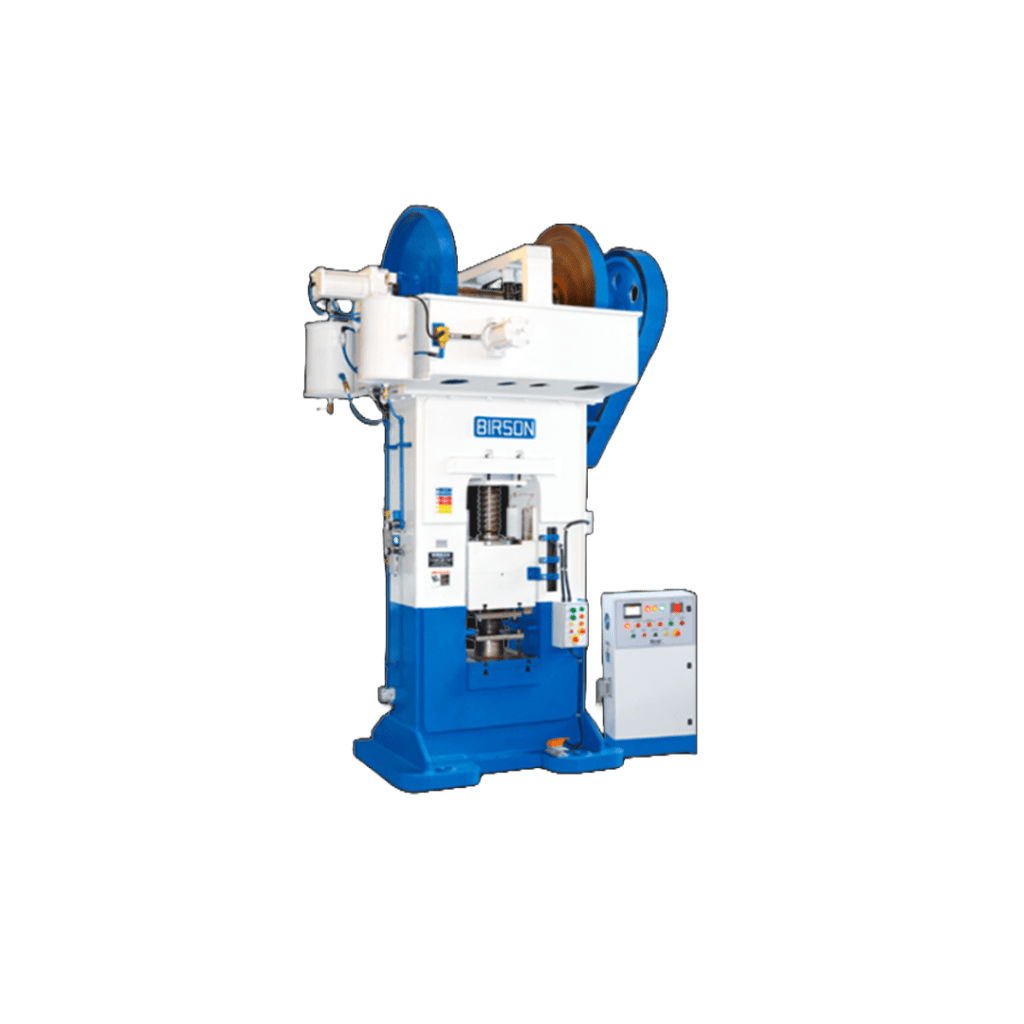

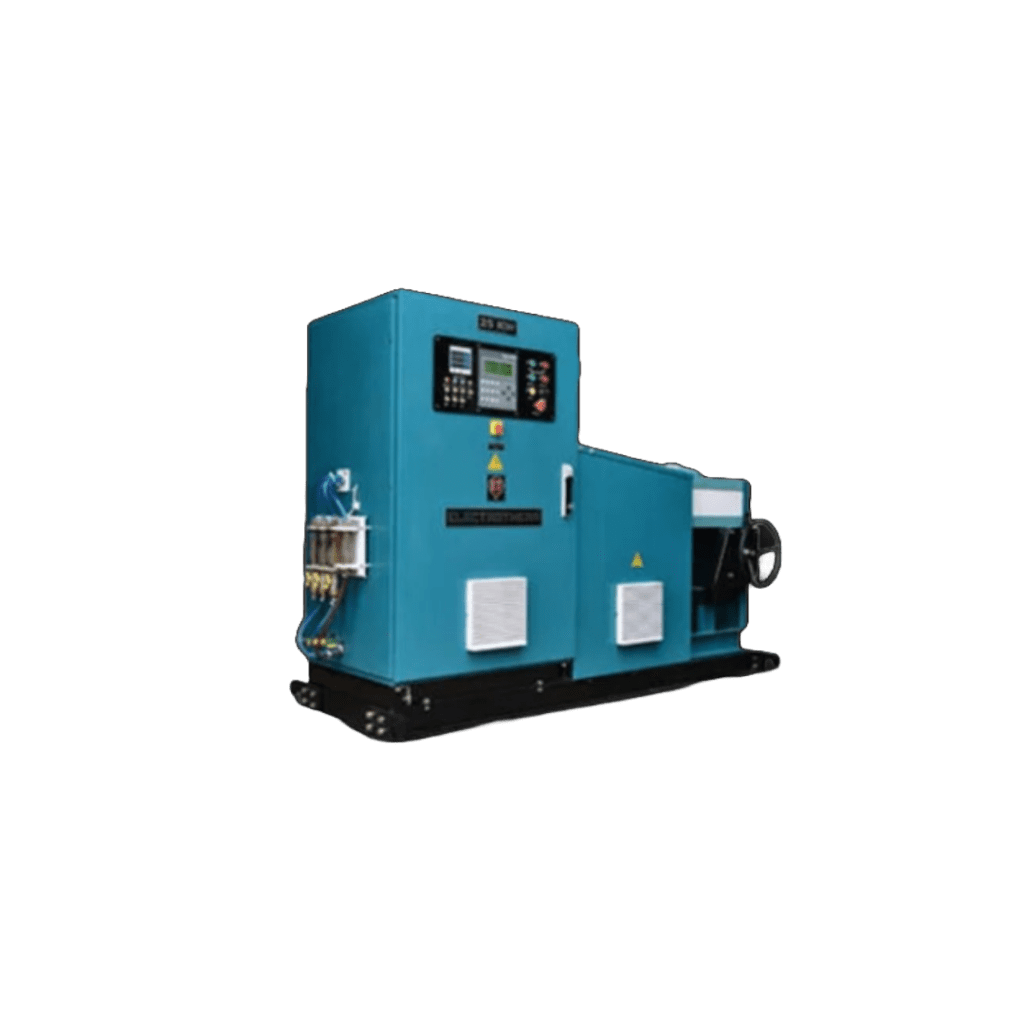

Elevate your expectations with our stellar lineup of equipment.

Please leave your message and our team will get back to you soon!